- Product available through Competence Partner Program

- LINX-153 / LINX-154 Datasheet

- Installation Instructions: LINX-153 / LINX-154

- L-INX / L-GATE User Manual

- Certificates: EC / BTL / UL / AMEV

- Downloads: LINX-153 / LINX-154

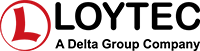

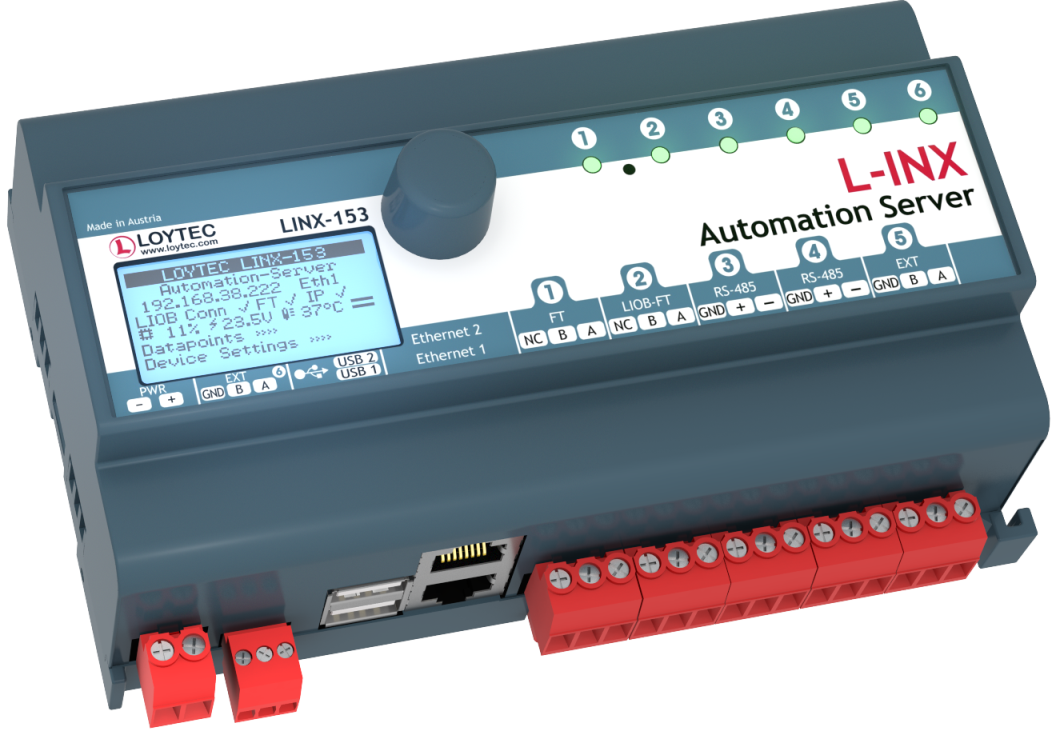

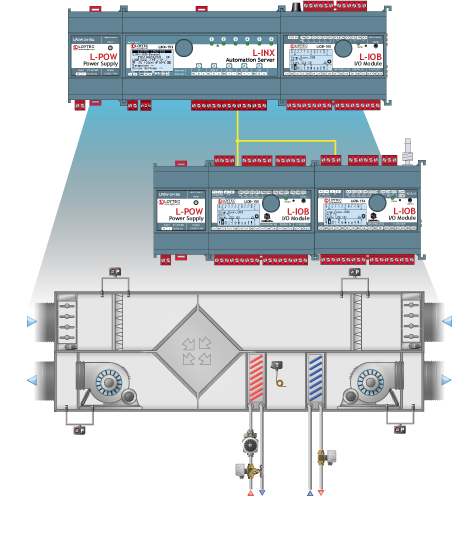

The L‑INX Automation Servers LINX‑153 and LINX‑154 are powerful, programmable automation stations, which can be programmed by L‑STUDIO. The L‑INX Automation Servers can host user specific graphical pages and can integrate physical I/Os through L‑IOB I/O Modules via LIOB‑Connect, LIOB‑FT, or LIOB‑IP. The LINX‑154 can only be extended by LIOB‑IP. Local operation and override is provided by the built-in jog dial and the backlit display (128x64 pixels). Device and data point information is shown on the display via symbols and in text format.

The powerful Automation Servers provide connectivity functions to concurrently integrate CEA‑709 (LonMark Systems), BACnet, KNX, Modbus, and M‑Bus subsystems. LonMark Systems can be integrated via IP‑852 (Ethernet/IP) or TP/FT‑10. BACnet integration is supported through BACnet/IP (Ethernet/IP) or BACnet MS/TP (RS‑485). LINX‑153 Automation Servers feature an integrated Remote Network Interface (RNI) to access the TP/FT‑10 channel on the device via Ethernet/IP. LINX‑153 Automation Servers feature two built-in routers, one IP‑852 router and one BACnet/IP to MS/TP router including BBMD as well as Slave-Proxy functionality providing the complete feature set of the corresponding L-IP devices.

The LINX‑153 and LINX‑154 implement the BACnet Building Controller (B-BC) profile and are BTL certified. In addition, the LINX‑15x provide connectivity to KNXnet/IP (only LINX‑153) and Modbus TCP via Ethernet/IP and to Modbus RTU/ASCII via RS‑485. M‑Bus and KNX TP1 (only for LINX‑153) device integration needs optional interface modules.

The gateway functionality allows data communication between all communication technologies available on the device. Different technology data points are mapped through Local Connections on the device. The mapping of different technology data points on distributed devices is supported by Global Connections. L‑INX Automation Servers also support Smart Auto-Connect™ – the automatic generation of connections to substantially reduce engineering efforts and cost. All technology data points are automatically created as OPC XML‑DA and OPC UA data points.

Each L‑INX Automation Server is equipped with two Ethernet ports. It can either be configured to use the internal switch to interconnect the two ports or every port is configured to work in a separate IP network.

When the Ethernet ports are configured for two separate IP networks, one port can be connected for instance to a WAN (Wide Area Network) with enabled network security (HTTPS) while the second port can be configured to be connected to an insecure network (LAN) where the standard building automation protocols like BACnet/IP, LON/IP, or Modbus TCP are present. These devices also feature firewall functionality of course to isolate particular protocols or services between the ports.The built-in VPN function provides for simple VPN setup and secure access to remote sites. The LTE-800 interface enables wireless access to remote sites through a mobile carrier.

Using the internal switch, a daisy chained line topology of up to 20 devices can be built, which reduces costs for network installation. The IP switch also allows the setup of a redundant Ethernet installation (ring topology), which increases reliability. The redundant Ethernet topology is enabled by the Rapid Spanning Tree Protocol (RSTP), which is supported by most managed switches.

The L‑INX devices provide fully featured AST™ functionality (Alarming, Scheduling, and Trending) and can be integrated perfectly into the L‑WEB System.

IoT Integration

The IoT function (Node.js) allows connecting the system to almost any cloud service, either for uploading historical data to analytics services, delivering alarm messages to alarm processing services or operating parts of the control system over a cloud service (e.g., scheduling based on Web calendars or booking systems). Processing Internet information such as weather data in forecast-based control is also possible. Finally, the JavaScript kernel also allows implementing serial protocols to non-standard equipment in primary plant control.

Features

- Programmable with L‑STUDIO IEC 61131‑3 and IEC 61499

- Room controller for up to 8 room segments

- Physical inputs and outputs with L‑IOB I/O Modules (LIOB‑11x, LIOB‑15x, and LIOB‑45x/55x for LINX‑153) (LIOB‑45x/55x for LINX‑154)

- 128x64 graphic display with backlight

- Local and remote access to information about device status and data points

- Manual operation using the jog dial or VNC client

- Alarming, Scheduling, and Trending (AST™)

- Node.js support for easy IoT integration (e.g. Google calendar, Alexa & friends, multimedia equipment,…)

- Event-driven e-mail notification

- Math objects to execute mathematical operations on data points

- Stores customized graphical pages

- Visualization of customized graphical pages through LWEB‑900 (Building Management), LWEB‑803 (Monitoring and Control), or LWEB‑802 (Web Browser)

- Built-in OPC XML-DA and OPC UA server

- Dual switched or separated Ethernet port

- Access to network statistics

- Compliant with ANSI/ASHRAE–135‑2012 and ISO 16484‑5:2012 standard

- Supports BACnet MS/TP, BACnet/IP or BACnet/SC

- BACnet Client Function (Write Property, Read Property, COV Subscription)

- BACnet Client Configuration with configuration tool (scan and EDE import)

- B-BC (BACnet Building Controller) functionality, BTL certified

- Compliant with CEA‑709, CEA‑852, and ISO/IEC 14908 Standard (LonMark System)

- Supports TP/FT‑10 (only LINX-153)

- Support of dynamically created or static NVs

- Support of user-defined NVs (UNVTs) and Configuration Properties (SCPTs, UCPTs)

- Remote Network Interface (RNI) with 2 MNI devices (only LINX-153)

- Integrated BACnet/ IP to BACnet/SC and BACnet MS/ TP Router including BBMD as well as Slave-Proxy functionality

- Integrated IP‑852 to TP/FT‑10 Router(only LINX-153)

- KNXnet/IP, connection to KNX TP1 through LKNX-300 Interface (only LINX-153)

- M-Bus Master according to EN 13757-3, connection via optional M‑Bus Converter (only LINX-153)(L‑MBUS20 or L‑MBUS80)

- Gateway functions including Smart Auto-Connect™

- Modbus TCP and Modbus RTU/ASCII (Master or Slave)

- Integrated web server for device configuration and monitoring data points

- Configurable via TP/FT‑10 (only LINX-153) or Ethernet/IP

- Connection to EnOcean wireless devices via L-ENO Interface (only LINX-153)

- Supports SMI (Standard Motor Interface) through LSMI-800 or LSMI-804 (only LINX‑153)

- Supports MP-Bus through LMPBUS‑804 Interface (only LINX‑153)

- Supports WLAN through LWLAN-800 Interface

- Supports LTE through LTE-800 Interface

- Stores user-defined project documentation

Tutorials

Features of L-INX 8.0 Release

This video presents some features of the new firmware release.

How to create schedulers (CEA-709) [A001]

This tutorial describes how to create schedulers on an L-VIS Touch Panel with the configuration tool L-VIS Configurator.

How to create a calendar including exception days (CEA-709) [A002]

This tutorial describes how to create a calendar including exception days on an L-VIS Touch Panel with the configuration tool L-VIS Configurator.

How to operate a scheduler on the web interface of a L-INX Automation Server [A004]

This tutorial describes how to use the Web UI of the L-INX Automation Server.

How to create a remote scheduler (CEA-709) [A005]

This tutorial describes how to create a remote scheduler on the L-INX Automation Server with the configuration tool NL220 LonWorks© Manager.

How to create alarms (CEA-709) [A006]

This tutorial describes how to create alarms on the L-INX Automation Server with the configuration tool L-INX Configurator.

How to use e-mail configuration [A007]

This tutorial describes how to configure the L-INX Automation Server with the configuration tool L-INX Configurator.

How to create trend objects [A008]

This tutorial describes how to create trend objects on the L-INX Automation Server with the configuration tool L-INX Configurator.

How to create schedulers on BACnet devices [A201]

This tutorial describes how to create schedulers on BACnet devices on the L-INX Automation Server with the configuration tool L-INX Configurator.

How to create a calendar on BACnet devices [A202]

This tutorial describes how to create a calendar on the L-INX Automation Server with the configuration tool L-INX Configurator.

How to create a remote scheduler on BACnet devices [A205]

This tutorial describes how to create a remote scheduler on the L-INX Automation Server with the configuration tool L-INX Configurator.

How to create alarms on BACnet devices [A206]

This tutorial describes how to create alarms on the L-INX Automation Server with the configuration tool L-INX Configurator.

How to create static network variables [B001]

This tutorial describes how to create static network variables on the L-INX Automation Server with the configuration tool L-INX Configurator.

How to create dynamic network variables [B002]

This tutorial describes how to create dynamic network variables on the L-INX Automation Server with the configuration tool NL220 LonWorks© Manager.

How to create network variables by using LNS scan [B003]

This tutorial describes how to create network variables by using LNX scan on the L-INX Automation Server with the configuration tool L-INX Configurator.

How to create network variables by using network scan [B004]

This tutorial describes how to create network variables by using network scan on the L-INX Automation Server with the configuration tool L-INX Configurator.

How to import network variables by using CSV file import [B005]

This tutorial describes how to import network variables by using CSV file import on the L-INX Automation Server with the configuration tool L-INX Configurator.

How to import extern network variables (LNS scan or network scan) [B006]

This tutorial describes how to import extern network variables on the L-INX Automation Server with the configuration tool L-INX Configurator.

How to create network variables by using Filter Templates [B007]

This tutorial describes how to create network variables by using Filter Templates on the L-INX Automation Server with the configuration tool L-INX Configurator.

Manual creation of BACnet Server Objects [B201]

This tutorial describes how to create BACnet Server Objects manually on the L-INX Automation Server with the configuration tool L-INX Configurator.

How to create client mappings using network scan [B202]

This tutorial describes how to create client mappings using network scan on the L-INX Automation Server with the configuration tool L-INX Configurator.

How to create client mappings using EDE file import [B203]

This tutorial describes how to configure the L-INX Automation Server with the configuration tool L-INX Configurator.

Quick start scenario creating an L-WEB project [W001]

This tutorial describes how to create an L-WEB project and configure the L-INX Automation Server with the configuration tool L-INX Configurator.

A quick start scenario creating an L-WEB database [W002]

This tutorial describes how to create a database with the LWEB Server and the configuration tool L-INX Configurator on the example of configuring the L-INX Automation Server.

How to create data points using M-Bus Network Scan [L001]

This tutorial describes how to create data points using M-Bus Network Scan on the L-INX Automation Server with the configuration tool L-INX Configurator.

How to create and use M-Bus device templates [L002]

This tutorial describes how to create and use M-Bus device templates on the L-INX Automation Server with the configuration tool L-INX Configurator.

LINX-153/154 Automation Server Products | |

LINX-153 | |

| BACnet & CEA‑709 Automation Server with LIOB‑Connect (No L-LOGICAD support from July 1, 2023) |

Start quote request Start quote request Documentation and Software Documentation and Software | |

3D View 3D View | |

e0da2cbf3cf54747a8444525c8dc53e5 | |

LINX-154 | |

| BACnet Automation Server with 4 RS-485 channels (No L-LOGICAD support from July 1, 2023) |

Start quote request Start quote request Documentation and Software Documentation and Software | |

3D View 3D View | |

3effc13bc27c44d2a1fe3b923416340b | |

L-STUDIO | |

| Development and integration platform for programmable LOYTEC controllers |

Start quote request Start quote request Documentation and Software Documentation and Software | |

LIOB-A2 | |

| L‑IOB Adapter 2 to split the LIOB‑Connect bus using 4-wire cables |

Start quote request Start quote request Documentation and Software Documentation and Software | |

3D View 3D View | |

6270d50d08a74b69ab8be97bca242b29 | |

LIOB-A4 | |

| L‑IOB Adapter 4 to split the LIOB‑Connect bus using RJ45 network cables |

Start quote request Start quote request Documentation and Software Documentation and Software | |

3D View 3D View | |

798babbffc92440b8bdb6445698fa381 | |

LIOB-A5 | |

| L‑IOB Adapter 5 to terminate the LIOB-Connect bus |

Start quote request Start quote request Documentation and Software Documentation and Software | |

3D View 3D View | |

3923a39c788f4a42b55a246006327dc1 | |

LIOB-100 | |

| LIOB-Connect I/O Module: 8 UI, 2 DI, 2 AO, 9 DO (5 x Relay 6 A, 4 x Triac 0.5 A) |

Start quote request Start quote request Documentation and Software Documentation and Software | |

3D View 3D View | |

a0bf19dfbe784dbaa9cd8f9cdb98c09d | |

LIOB-101 | |

| LIOB-Connect I/O Module: 8 UI, 16 DI |

Start quote request Start quote request Documentation and Software Documentation and Software | |

3D View 3D View | |

2f6e616c155041cdbe1aaa96984fb8f6 | |

LIOB-102 | |

| LIOB-Connect I/O Module: 6 UI, 6 AO, 8 DO (8 x Relay 6 A) |

Start quote request Start quote request Documentation and Software Documentation and Software | |

3D View 3D View | |

f8d461e56b73471bb2bd3e989c647829 | |

LIOB-103 | |

| LIOB-Connect I/O Module: 6 UI, 6 AO, 5 DO (5 x Relay 16 A) |

Start quote request Start quote request Documentation and Software Documentation and Software | |

3D View 3D View | |

3580ef64d7224d58b0b8df422b0e33aa | |

LIOB-110 | |

| LIOB-Connect I/O Module: 20 Universal I/O (IO) |

Start quote request Start quote request Documentation and Software Documentation and Software | |

3D View 3D View | |

fc37c4e2d8334dc9a4008a93fdeed68b | |

LIOB-112 | |

| LIOB‑Connect I/O Module: 40 Universal I/O (12 optionally with 4-20 mA Current Output) |

Start quote request Start quote request Documentation and Software Documentation and Software | |

3D View 3D View | |

a4c0124f6524494b937e4a77bdc9a9cf | |

LIOB-150 | |

| LIOB-FT I/O Module: 8 UI, 2 DI, 2 AO, 8 DO (4 x Relay 6 A, 4 x Triac 0.5 A) |

Start quote request Start quote request Documentation and Software Documentation and Software | |

3D View 3D View | |

e8af7c6b82b54b7f8dee3c61d3cb99d5 | |

LIOB-151 | |

| LIOB-FT I/O Module: 8 UI, 12 DI |

Start quote request Start quote request Documentation and Software Documentation and Software | |

3D View 3D View | |

5589833098ec4e57ab8a09b1e6be3318 | |

LIOB-152 | |

| LIOB-FT I/O Module: 6 UI, 6 AO, 8 DO (8 x Relay 6 A) |

Start quote request Start quote request Documentation and Software Documentation and Software | |

3D View 3D View | |

9e4a0bcbc7d54da0af20dd7f4d082862 | |

LIOB-153 | |

| LIOB-FT I/O Module: 6 UI, 6 AO, 5 DO (4 x Relay 16 A, 1 x Relay 6 A) |

Start quote request Start quote request Documentation and Software Documentation and Software | |

3D View 3D View | |

ec9fdbf9b98f4c7e9a31b151785763bf | |

LIOB-154 | |

| LIOB-FT I/O Module: 7 UI, 4 AO, 7 DO (5 x Relay 6 A, 2 x Triac 0.5 A), 1 Pressure Sensor |

Start quote request Start quote request Documentation and Software Documentation and Software | |

3D View 3D View | |

e803e995b7c94953852eac4c8840d00c | |

LIOB-450 | |

| LIOB-IP852 I/O Module: 8 UI, 2 DI, 2 AO, 8 DO (4 x Relay 6 A, 4 x Triac 0.5 A) |

Start quote request Start quote request Documentation and Software Documentation and Software | |

3D View 3D View | |

25d3fded9d2c4c53b64d7615bada19f7 | |

LIOB-451 | |

| LIOB-IP852 I/O Module: 8 UI, 12 DI |

Start quote request Start quote request Documentation and Software Documentation and Software | |

3D View 3D View | |

3c8677b55a714192848a0642ad12d81d | |

LIOB-452 | |

| LIOB-IP852 I/O Module: 6 UI, 6 AO, 8 DO (8 x Relay 6 A) |

Start quote request Start quote request Documentation and Software Documentation and Software | |

3D View 3D View | |

d806ef3909104ac9af56af181171e710 | |

LIOB-453 | |

| LIOB-IP852 I/O Module: 6 UI, 6 AO, 5 DO (4 x Relay 16 A, 1 x Relay 6 A) |

Start quote request Start quote request Documentation and Software Documentation and Software | |

3D View 3D View | |

abcfc60dd47349cca6e88c6f1bd85bb8 | |

LIOB-454 | |

| LIOB-IP852 I/O Module: 7 UI, 4 AO, 7 DO (5 x Relay 6 A, 2 x Triac 0.5 A), 1 Pressure Sensor |

Start quote request Start quote request Documentation and Software Documentation and Software | |

3D View 3D View | |

4222af0f977e4d879f1e1ea511ab8e9d | |

LIOB-550 | |

| LIOB-BIP I/O Module: 8 UI, 2 DI, 2 AO, 8 DO (4 x Relay 6 A, 4 x Triac 0.5 A) |

Start quote request Start quote request Documentation and Software Documentation and Software | |

3D View 3D View | |

e3cb2c23d25743a9a5e08e738e4d98b4 | |

LIOB-551 | |

| LIOB-BIP I/O Module: 8 UI, 12 DI |

Start quote request Start quote request Documentation and Software Documentation and Software | |

3D View 3D View | |

67b4415097fe4bf58d9e7b2d72bf072a | |

LIOB-552 | |

| LIOB-BIP I/O Module: 6 UI, 6 AO, 8 DO (8 x Relay 6 A) |

Start quote request Start quote request Documentation and Software Documentation and Software | |

3D View 3D View | |

cba6222b52144860962d4b206cb02b6f | |

LIOB-553 | |

| LIOB-BIP I/O Module: 6 UI, 6 AO, 5 DO (4 x Relay 16 A, 1 x Relay 6 A) |

Start quote request Start quote request Documentation and Software Documentation and Software | |

3D View 3D View | |

0ec3f981082f4d0d8a1cf9d4d0bc45c7 | |

LIOB-554 | |

| LIOB-BIP I/O Module: 7 UI, 4 AO, 7 DO (5 x Relay 6 A, 2 x Triac 0.5 A), 1 Pressure Sensor |

Start quote request Start quote request Documentation and Software Documentation and Software | |

3D View 3D View | |

040798d7f41f4f51aac750c642a2d4fc | |

LPOW-2415A | |

| LIOB-Connect Power Supply, 24 VDC, 15 W |

Start quote request Start quote request Documentation and Software Documentation and Software | |

3D View 3D View | |

bf6ff2e52c15478091e6b057aec2452c | |

LPOW-2415B | |

| Power supply unit with power connector 24 VDC, 15 W |

Start quote request Start quote request Documentation and Software Documentation and Software | |

3D View 3D View | |

c2eacbb15ec04078becb106cf02fe7ed | |

L-MBUS20 | |

| M-Bus level converter, interface for 20 M-Bus devices |

Start quote request Start quote request Documentation and Software Documentation and Software | |

3D View 3D View | |

e652d00e44a64759a08508e069015c22 | |

L-MBUS80 | |

| M-Bus Level Converter, Interface for up to 80 M-Bus devices |

Start quote request Start quote request Documentation and Software Documentation and Software | |

3D View 3D View | |

d0a18d275fe64135826638032b3223e9 | |

LKNX-300 | |

| KNX interface to connect KNX TP1 devices |

Start quote request Start quote request Documentation and Software Documentation and Software | |

3D View 3D View | |

1a43e3eb71ca4d23b4e22a6805dd2bd9 | |

LENO-800 | |

| EnOcean Interface 868 MHz Europe |

Start quote request Start quote request Documentation and Software Documentation and Software | |

3D View 3D View | |

3388466f6f1d45adb75659c84b6eae7c | |

LENO-801 | |

| EnOcean Interface 902 MHz USA/Canada |

Start quote request Start quote request Documentation and Software Documentation and Software | |

3D View 3D View | |

eb7530e32b764531af31f5221b303fc3 | |

LENO-802 | |

| EnOcean Interface 928 MHz Japan |

Start quote request Start quote request Documentation and Software Documentation and Software | |

3D View 3D View | |

b35cd07b9a2c4caea8708199d97d7a84 | |

LWLAN-800 | |

| Wireless LAN Interface IEEE 802.11bgn |

Start quote request Start quote request Documentation and Software Documentation and Software | |

3D View 3D View | |

0cbc0ae8402248c6978a6b1769a2844b | |

LMPBUS-804 | |

| MP-Bus Interface for 16 devices per channel, up to 4 channels |

Start quote request Start quote request Documentation and Software Documentation and Software | |

3D View 3D View | |

b4e845276b3d4fb4afb7713433df6e55 | |

LSMI-800 | |

| Standard Motor Interface for 16 motors via EXT port |

Start quote request Start quote request Documentation and Software Documentation and Software | |

3D View 3D View | |

f73b956efe9a42ae92a66c4a2c2e953a | |

LSMI-804 | |

| Standard Motor Interface (high voltage) for 64 motors, 4 SMI channels via USB |

Start quote request Start quote request Documentation and Software Documentation and Software | |

3D View 3D View | |

da0579f69819419a9be87274db8907d0 | |

LRS232-802 | |

| USB to 2x RS-232 Interface (please read EOL PCN073) |

Start quote request Start quote request Documentation and Software Documentation and Software | |

3D View 3D View | |

ae11a764f6c34a4eabd563f46bfd1ea1 | |

LIOB-560 | |

| LIOB-BIP I/O Modul: 20 Universal I/O (IO) |

Start quote request Start quote request Documentation and Software Documentation and Software | |

3D View 3D View | |

1c74f3453054428ca1140089c6e3287c | |

LIOB-562 | |

| LIOB-BIP I/O Module: 40 Universal I/O (12 optionally with 4-20 mA Current Output) |

Start quote request Start quote request Documentation and Software Documentation and Software | |

3D View 3D View | |

a5fcd1c326ed45c4815ff87cb80fa6d2 | |